Understanding Tracing Paper and Its Uses

Tracing paper is a semi-transparent paper primarily used for copying images, technical drawings, patterns, and artwork. Its unique transparency allows designers, architects, and artists to overlay the paper onto an original image to trace precise details. Understanding the properties of tracing paper, including weight, transparency, and finish, is essential for selecting the right type for specific projects.

Tracing paper is widely applied in fields such as architecture, engineering, fashion design, illustration, and educational settings. Each application may require a different level of transparency, smoothness, and durability, making informed selection a key factor in achieving optimal results.

Selecting the Right Weight of Tracing Paper

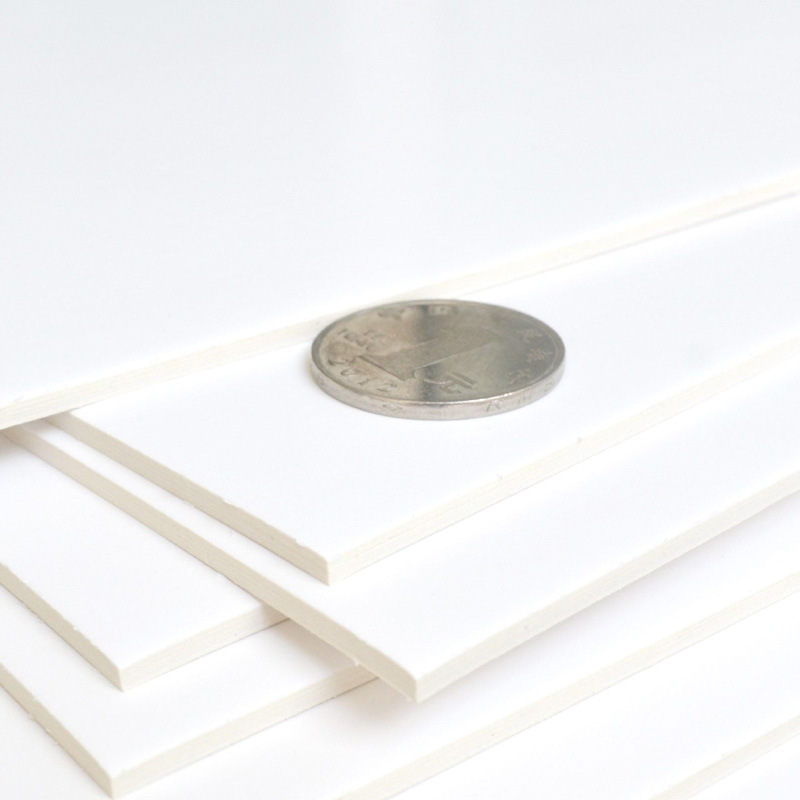

The weight of tracing paper, typically measured in grams per square meter (gsm), directly affects its durability, flexibility, and ease of use. Lighter papers (ranging from 40 to 80 gsm) are thinner, allowing higher transparency for tracing intricate details but may tear easily. Heavier papers (90 gsm and above) are more robust, resist wrinkling, and can withstand repeated handling without compromising clarity.

Choosing the appropriate weight depends on the intended application. For single-use tracing or fine detail work, lighter papers provide maximum clarity. For repeated tracing, overlaying, or long-term preservation, heavier papers ensure longevity and maintain structural integrity.

Transparency and Its Impact on Tracing Accuracy

Transparency determines how easily the underlying image can be seen and traced accurately. High-transparency tracing paper allows for precise replication of fine lines and details, essential for technical drawings, pattern transfers, and detailed illustrations. Low-transparency or frosted paper may reduce visibility, making it more suitable for rough sketches or layering purposes where exact precision is not required.

Factors Affecting Transparency

- Paper weight: Heavier papers often have slightly lower transparency.

- Surface coating: Papers with smooth or coated finishes may appear slightly more opaque.

- Material composition: Fibers and pulp density influence clarity and translucency.

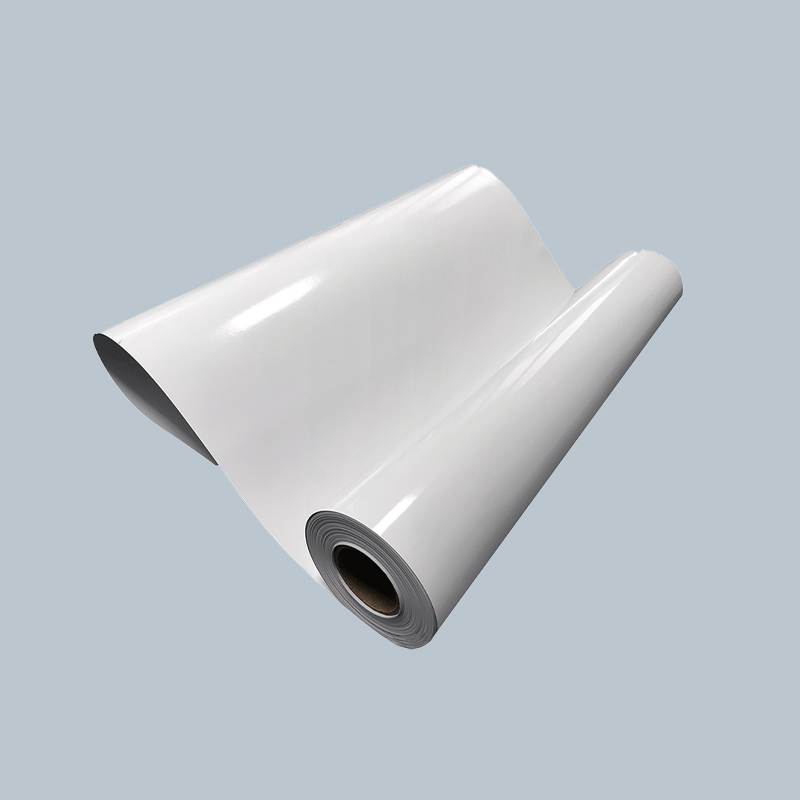

Understanding the Finish of Tracing Paper

The finish of tracing paper affects how pencils, pens, ink, and markers interact with the surface. Smooth finishes allow fine lines and detailed ink work, while slightly textured finishes provide grip for pencil or charcoal shading without smudging. Some tracing papers may include coated finishes for enhanced ink absorption or protection against smearing.

The choice of finish is closely tied to the medium being used. For example, smooth, high-quality finishes are ideal for ink or digital printing, while lightly textured papers are preferred for pencil, charcoal, or pastel work. Selecting the appropriate finish ensures clean, precise results and reduces the risk of ink bleeding or smudging.

Comparing Tracing Paper Options

| Type | Weight (gsm) | Transparency | Recommended Use |

| Lightweight Tracing Paper | 40–60 | High | Detailed sketches, single-use tracing |

| Medium Weight Tracing Paper | 70–90 | Medium to High | Pattern transfer, repeated tracing |

| Heavyweight Tracing Paper | 100+ | Medium | Long-term projects, archival work |

Special Considerations for Tracing Paper Selection

In addition to weight, transparency, and finish, other factors such as size, durability, and environmental resistance should be considered. Large sheets may be required for architectural or engineering drawings, while smaller pads are convenient for sketching and craft projects. Acid-free and archival-grade papers are important for projects that need long-term preservation.

Understanding the specific needs of your project ensures you select a tracing paper that balances usability, durability, and quality. Evaluating all these factors before purchase reduces errors, improves workflow efficiency, and produces better final results.

Conclusion: Choosing the Right Tracing Paper

Selecting the right tracing paper involves careful consideration of weight, transparency, and finish to match the intended use. By understanding the differences in paper types, adhesive compatibility, and performance under various conditions, artists, designers, and technical professionals can ensure accurate results and durable outputs. Making informed choices ultimately enhances productivity, precision, and the overall quality of the finished work.

English

English عربى

عربى Español

Español