Understanding Bond and Coated CAD Plotter Paper

CAD plotter paper is a fundamental material in architectural, engineering, and design applications. Selecting the right type of paper—bond or coated—affects print quality, durability, and usability. Bond paper is widely used for general technical drawings due to its affordability and smooth surface, while coated paper offers enhanced image clarity, ink absorption, and resistance to smudging. Understanding the characteristics of each type allows designers and engineers to match paper performance to project requirements.

Characteristics of Bond CAD Plotter Paper

Bond CAD plotter paper is uncoated, lightweight, and designed for high-speed printing of technical drawings, blueprints, and schematics. Its surface provides adequate ink absorption for most line work, and it is generally compatible with both inkjet and plotter printers. Bond paper is typically more cost-effective than coated paper, making it ideal for large-volume projects where clarity and precision requirements are standard rather than critical.

- Smooth, uncoated surface suitable for standard line drawings

- Lightweight and cost-efficient for bulk printing

- Works well with inkjet, laser, and conventional plotters

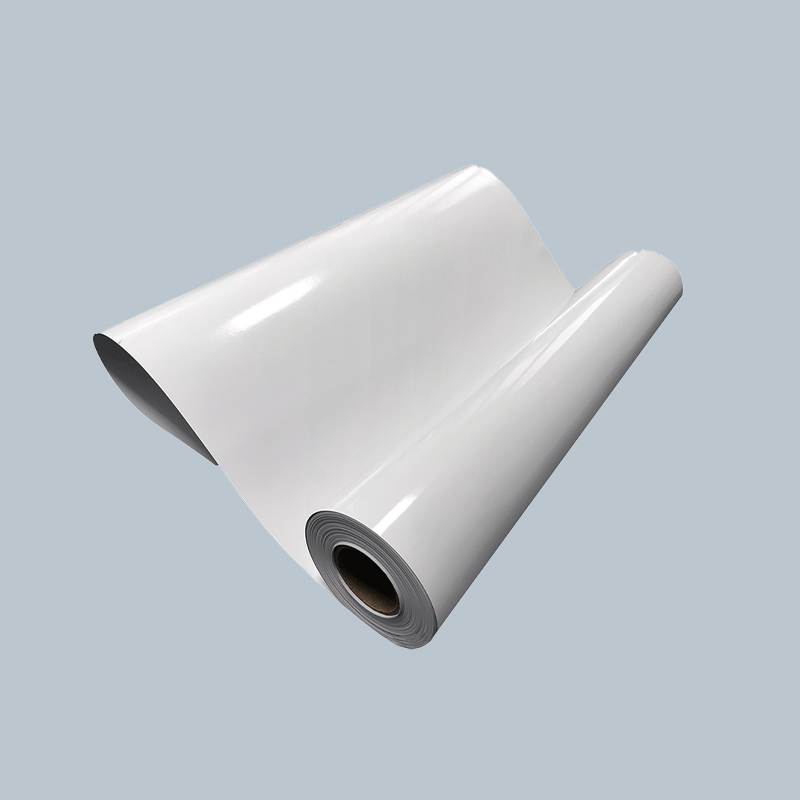

Characteristics of Coated CAD Plotter Paper

Coated CAD plotter paper features a layer that improves ink absorption, sharpness, and line definition. This coating enhances print durability and reduces smudging, making it suitable for high-precision drawings, presentations, and archival purposes. Coated paper is slightly heavier than bond paper and is often selected for documents requiring superior image quality or for final submission of technical plans.

- Smooth, coated surface for crisp lines and high-resolution prints

- Reduces smudging and improves handling durability

- Suitable for presentation-quality drawings and technical submissions

Comparing Bond and Coated CAD Plotter Paper

Selecting between bond and coated CAD plotter paper depends on project type, desired print quality, and budget. While bond paper is sufficient for internal drafts and standard line drawings, coated paper is preferred when clarity, precision, and presentation quality are critical. Evaluating these factors ensures efficient printing and reduces material waste.

| Feature | Bond Paper | Coated Paper |

| Surface | Uncoated, smooth | Coated, smooth, ink-enhancing |

| Print Quality | Standard, suitable for drafts | High precision, sharp lines |

| Durability | Moderate, best for short-term use | High, resistant to smudging and handling |

| Cost | Lower, budget-friendly | Higher, suitable for professional presentation |

| Best Use | Drafts, internal plans, bulk printing | Presentations, final submissions, high-resolution drawings |

Making the Right Choice for Your Projects

When deciding between bond and coated CAD plotter paper, consider the intended use, printing volume, and required image quality. Bond paper is ideal for cost-effective, high-volume drafting and internal documentation. Coated paper is best for projects requiring precision, durability, and professional presentation. Understanding the differences ensures optimal results, reduces material waste, and supports efficient workflow in design and engineering applications.

English

English عربى

عربى Español

Español