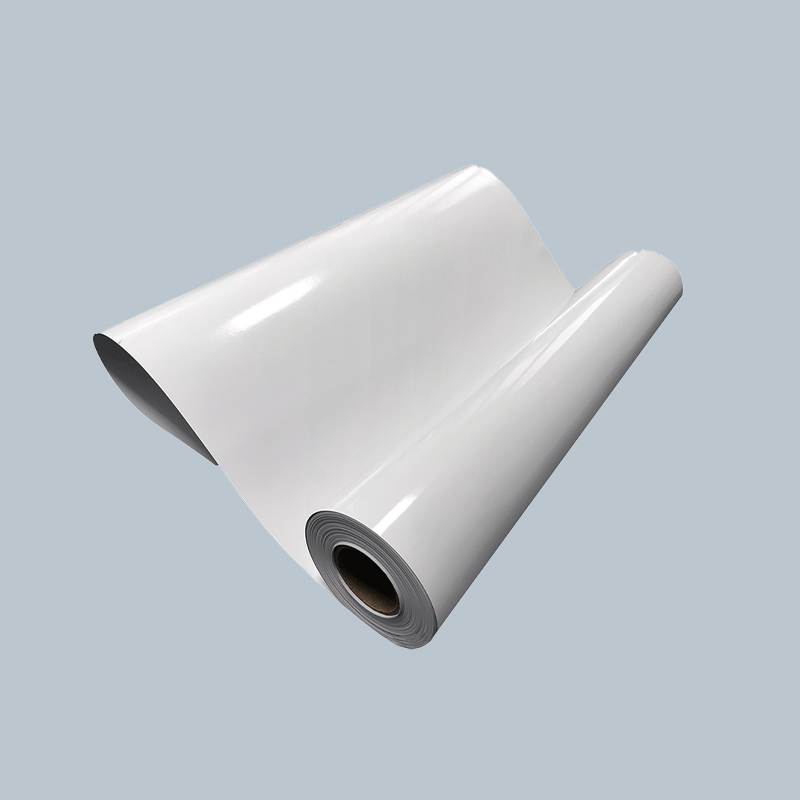

White CAD plotter paper is designed to meet the demanding requirements of architectural, engineering, and technical drawings, which require precise line definition, durability, and clarity. To achieve these properties, manufacturers apply specialized coating technologies that significantly enhance the paper’s surface characteristics. These coatings serve multiple purposes, including improving water resistance to protect prints from accidental spills or humidity, providing smudge resistance to maintain image integrity immediately after printing, and ensuring strong compatibility with various ink types to preserve sharpness and color accuracy.

1. Polymer-Based Coatings for Water Resistance and Surface Smoothness

One of the most common treatments for CAD plotter paper involves the application of polymer coatings, typically thin layers of polyethylene, acrylics, or other synthetic polymers. These coatings act as a protective barrier on the paper surface, significantly reducing water penetration into the paper fibers. By limiting water absorption, these polymer layers help prevent ink from spreading or bleeding, which is critical for maintaining crisp lines and fine details in technical drawings.

Moreover, these polymer coatings contribute to a smoother surface texture. A smooth finish improves the ink adhesion for inkjet and laser printing technologies, allowing for consistent and uniform ink deposition. This results in sharper lines and better print resolution, essential for architectural blueprints and engineering schematics where accuracy is paramount.

2. Sizing Agents to Control Ink Absorption and Enhance Water Resistance

In addition to surface coatings, sizing agents play a vital role in improving the paper’s performance. Sizing involves treating the paper fibers either internally during manufacturing or externally on the surface with substances like modified starches or synthetic polymers. These agents adjust the paper’s absorption properties, controlling the rate at which ink penetrates the fibers.

Proper sizing prevents ink from spreading beyond the intended areas (a phenomenon known as feathering), thus preserving the sharp edges of fine lines and text. It also enhances water resistance by making the fibers less hydrophilic, meaning the paper is less likely to soak up moisture from the environment or liquid contact, further protecting the printed content.

3. Silicone and Fluoropolymer Treatments for Smudge Resistance

Smudge resistance is particularly important for CAD papers used with inkjet printers, where the ink can remain wet for several seconds after printing. To mitigate smudging caused by handling, some CAD papers are treated with a silicone or fluoropolymer finish. These coatings create a repellent surface that reduces the likelihood of ink transfer when the paper is touched shortly after printing.

These finishes also help repel oils, dirt, and dust, which might otherwise degrade print quality or cause smearing. By promoting faster solvent evaporation from the ink surface, these coatings contribute to quicker drying times, improving productivity in fast-paced printing environments.

4. Matte and Satin Coatings for Optimized Visual Performance

Architectural and engineering prints often require a balance between minimizing glare and maximizing contrast. Matte or satin coatings are applied to the paper surface to diffuse reflected light, reducing glare that can obscure fine details during review or presentation.

These coatings also enhance the perceived sharpness and color contrast of prints, which is crucial when differentiating complex line work and color-coded elements in technical drawings. The coatings are formulated to be fully compatible with a range of ink chemistries, ensuring that colors and lines are reproduced accurately and consistently.

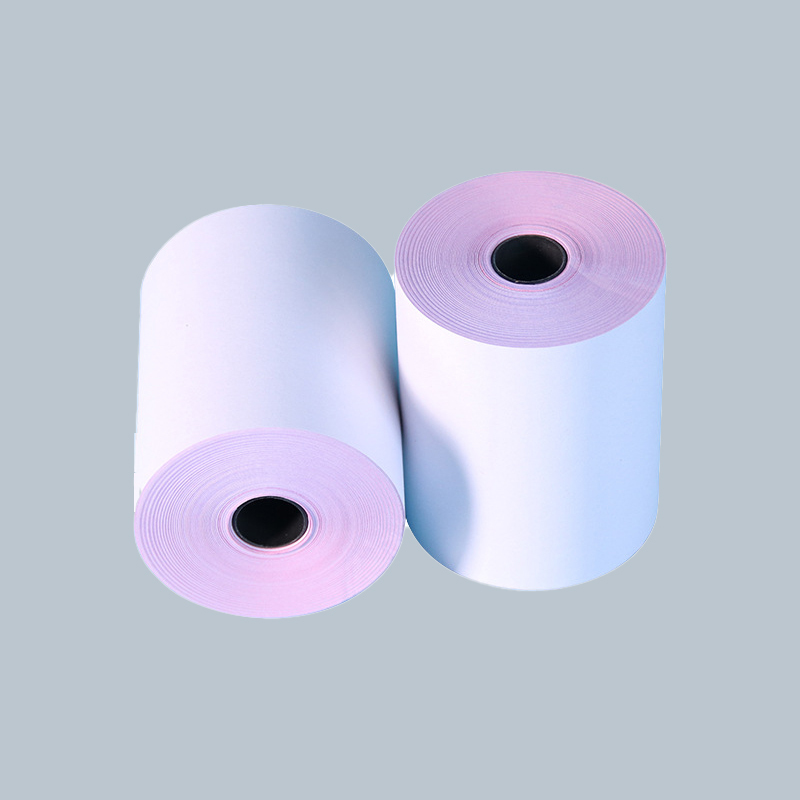

5. Ink Receptive Layers for Different Printing Technologies

Different printing methods, such as dye-based and pigment-based inkjet printing, laser printing, and solvent printing, each have unique requirements for paper surface properties. To optimize compatibility, CAD plotter paper is often coated with specialized ink receptive layers.

For example, pigment inks contain larger particles that require a porous or absorbent surface for proper fixation, whereas dye-based inks need a coating that prevents excessive spreading while enabling vivid coloration. Some coatings also improve adhesion for UV-curable and solvent inks used in more specialized industrial printing applications.

These coatings ensure that the printed lines and images exhibit excellent resolution, durability, and fade resistance, which is especially important for long-term archival or outdoor exposure of technical documents.

6. Additional Functional Coatings: Anti-Static and Anti-Curl Treatments

To improve printer performance and ease of handling, some white CAD plotter papers are treated with anti-static coatings that reduce static electricity build-up. Static charges can cause paper jams in printers and attract dust, potentially compromising print quality.

Furthermore, anti-curl coatings are applied to maintain the flatness of large-format sheets after printing. This is critical because curled or warped paper can affect the accuracy of multi-sheet overlays, complicate scanning or copying, and interfere with manual handling or filing.

The sophisticated coating technologies applied to white CAD plotter paper combine to deliver a product that:

-

Resists water and moisture, protecting printed content from environmental damage.

-

Reduces smudging and promotes fast ink drying, ensuring prints remain clear and clean immediately after production.

-

Offers superior ink adhesion and compatibility across diverse printing technologies, preserving the fidelity of intricate architectural and engineering designs.

-

Enhances visual clarity through matte or satin finishes that reduce glare and improve contrast.

-

Includes functional treatments to minimize static build-up and paper curling, improving printing reliability and user experience.

These combined technologies make white CAD plotter paper highly suited to the demanding conditions of professional design and drafting work, where precision, durability, and presentation quality are non-negotiable.

English

English عربى

عربى Español

Español