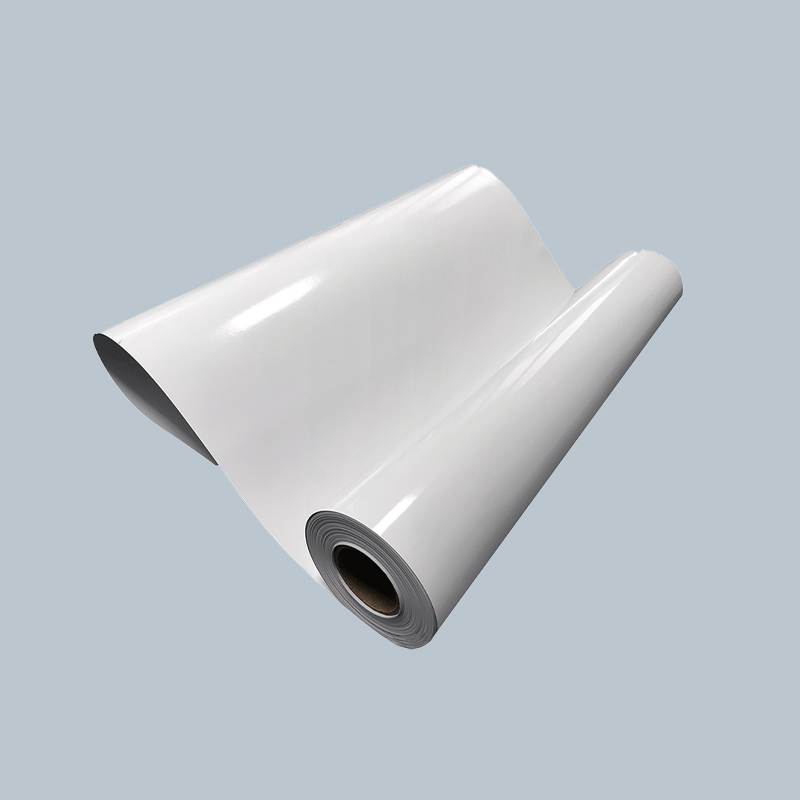

Folding Box Board (FBB paper) is a multilayer paperboard made from a combination of mechanical pulp and chemical pulp. Its structure is carefully engineered to balance strength, stiffness, printability, and cost-effectiveness, which makes it widely used for consumer packaging. Typically, FBB consists of three main layers:

-

Top Layer (Bleached Chemical Pulp)

- Made from high-quality bleached chemical pulp (virgin fibers).

- Provides a clean, white surface with excellent smoothness and brightness.

- Designed for superior printability, enabling sharp images, vibrant colors, and high-quality finishing.

- Often coated with one or more layers of mineral pigments (such as clay or calcium carbonate) to enhance print surface and gloss.

-

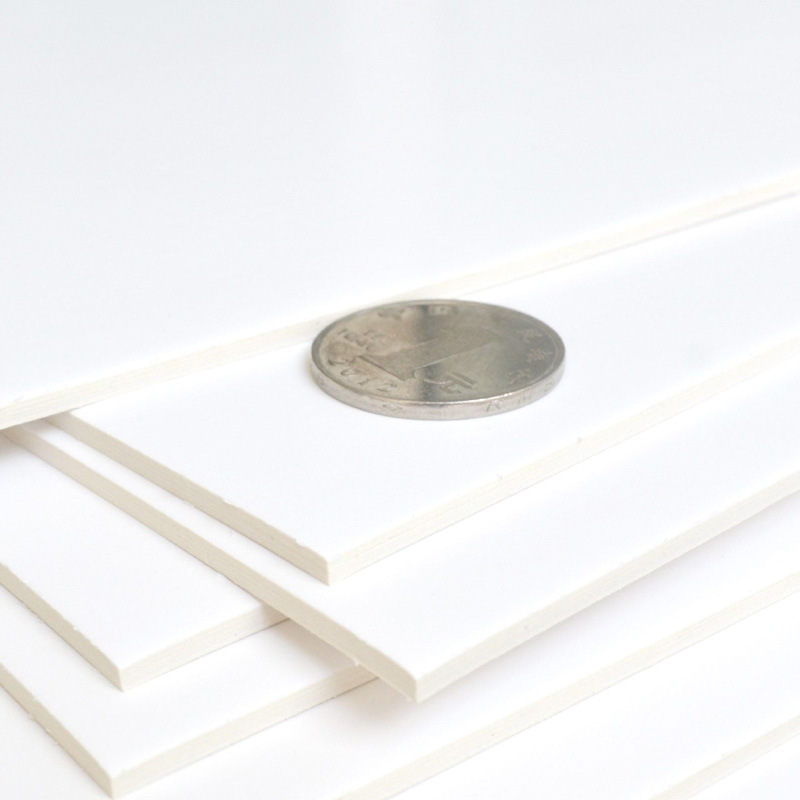

Middle Layer (Mechanical Pulp or CTMP – Chemi-ThermoMechanical Pulp)

- Bulk layer made from mechanical pulp, which retains more lignin and provides high stiffness and volume at relatively low weight.

- This layer is crucial for giving FBB its rigidity, allowing lightweight boards to still provide good strength.

- Helps reduce overall material consumption while maintaining packaging performance.

-

Back Layer (Bleached Chemical Pulp or Lightly Coated Surface)

- Made from bleached chemical pulp to ensure a consistent appearance and surface quality.

- Depending on the grade, the back may be uncoated, lightly coated, or fully coated for two-sided print applications.

- Provides additional strength and dimensional stability to the board.

Optional Surface Coatings

- Many FBB grades have additional coating layers (single, double, or triple coatings) on the top surface to further enhance smoothness, whiteness, and gloss.

- Specialized coatings can improve barrier properties against moisture, grease, or light, depending on packaging requirements.

Summary of the Structure

- Top Layer: Bleached chemical pulp (high brightness, print surface, often coated)

- Middle Layer: Mechanical pulp (bulk, stiffness, lightweight strength)

- Back Layer: Bleached chemical pulp (structural support, optional coating)

This layered structure makes FBB an ideal choice for folding cartons used in cosmetics, pharmaceuticals, food, and other consumer goods, where both visual appeal and structural performance are important.

English

English عربى

عربى Español

Español