When discussing CAD plotter paper, one of the most critical performance aspects is how it interacts with ink. The paper you choose directly influences ink absorption and line sharpness, which are essential factors in producing clear, precise, and professional technical drawings. For industries like architecture, engineering, garment design, and mechanical drafting, even small variations in print quality can affect readability and accuracy.

1. Ink Absorption and Its Role

Ink absorption refers to how quickly and evenly the paper takes in ink from the plotter. If the paper absorbs too much ink, lines may appear blurred, feathered, or faded, reducing clarity. On the other hand, if absorption is too low, the ink may remain wet on the surface longer, increasing the risk of smudging during handling.

High-quality CAD plotter paper is designed to provide balanced absorption, ensuring that ink settles quickly without spreading excessively. This allows fine lines, intricate patterns, and detailed measurements to remain intact.

2. Line Sharpness and Precision

Line sharpness is crucial in CAD drawings, where the difference between a clear, sharp edge and a blurred line can determine how well a design is understood. Paper with the right surface texture and coating helps keep lines crisp and well-defined, maintaining the accuracy of small-scale details. This is particularly important for:

- Architectural blueprints, where dimension lines must be easy to read.

- Engineering schematics, where overlapping symbols and technical notations require sharpness.

- Garment patterns, where smooth, continuous outlines guide cutting and assembly.

3. The Balance Between Paper Grade and Application

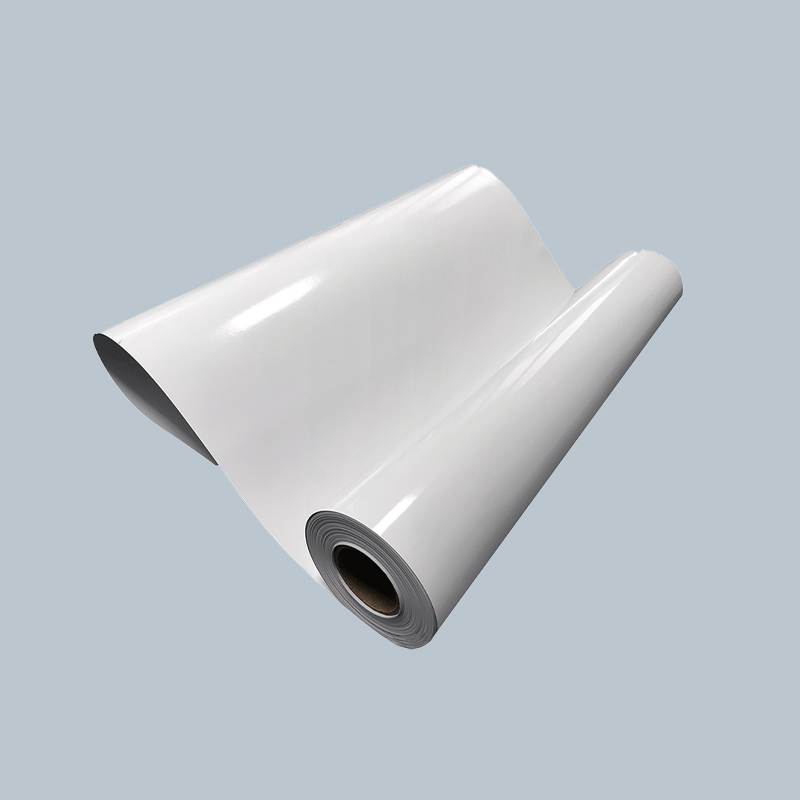

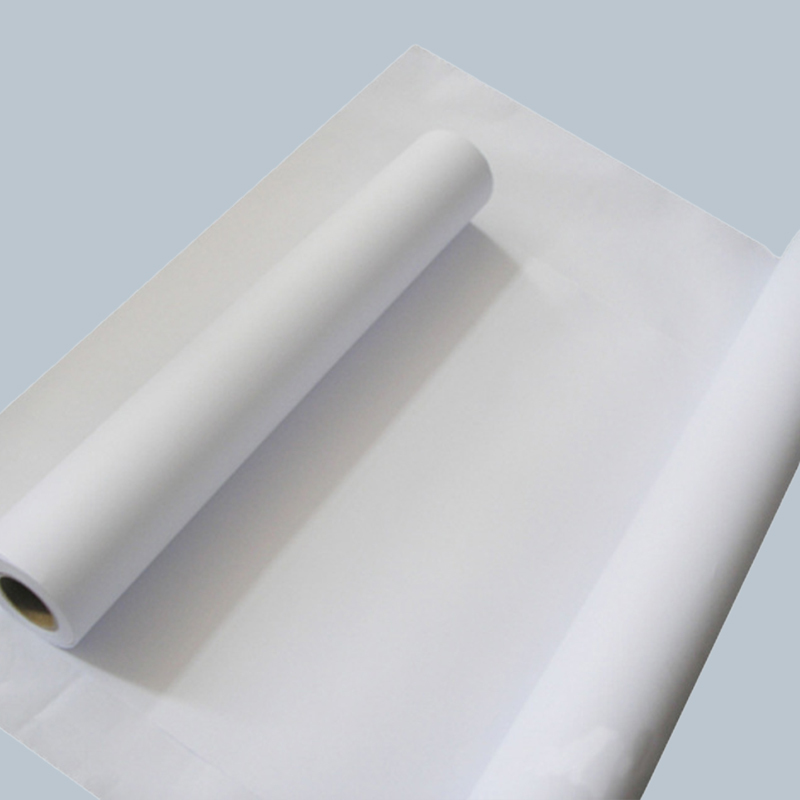

Different grades of CAD plotter paper are available, ranging from uncoated bond paper to coated high-brightness paper:

| Type of CAD Plotter Paper | Ink Absorption | Line Sharpness | Typical Use |

|---|---|---|---|

| Uncoated bond paper | Moderate, may feather slightly | Adequate for general drawings | Everyday drafting, internal reviews |

| Premium bond paper | Controlled absorption | High sharpness | Detailed technical drawings, client presentations |

| Coated plotter paper | Low absorption, ink sits on surface | Very high sharpness, strong contrast | Final blueprints, professional documents |

4. Environmental and Cost Considerations

While coated papers yield the best sharpness, they may be more expensive and less eco-friendly compared to uncoated alternatives. Companies often balance cost with required output quality, reserving premium papers for client-facing or archival documents while using basic bond paper for internal drafts.

5. Conclusion

The choice of CAD plotter paper is more than just a printing supply decision; it directly impacts the clarity, precision, and professional quality of technical drawings. By selecting paper with the right ink absorption characteristics and surface properties, designers and engineers can maintain sharp lines, accurate dimensions, and long-lasting readability, ensuring their work communicates effectively.

English

English عربى

عربى Español

Español