Overview — what determines FBB performance in converting

Folding Box Board (FBB) performance during folding, creasing, and die-cutting depends on base furnish, grammage, caliper, coating structure, bulk, and moisture content. Mechanical behaviour is governed by compressive strength of the top plies, bending stiffness, and the board’s ability to accept localized deformation at scores without surface cracking or internal delamination. This article gives practical, shop-floor guidance: recommended tooling, scoring depths, press and anvil settings, prepress tests, and common troubleshooting steps.

Material characteristics that directly affect scores and folds

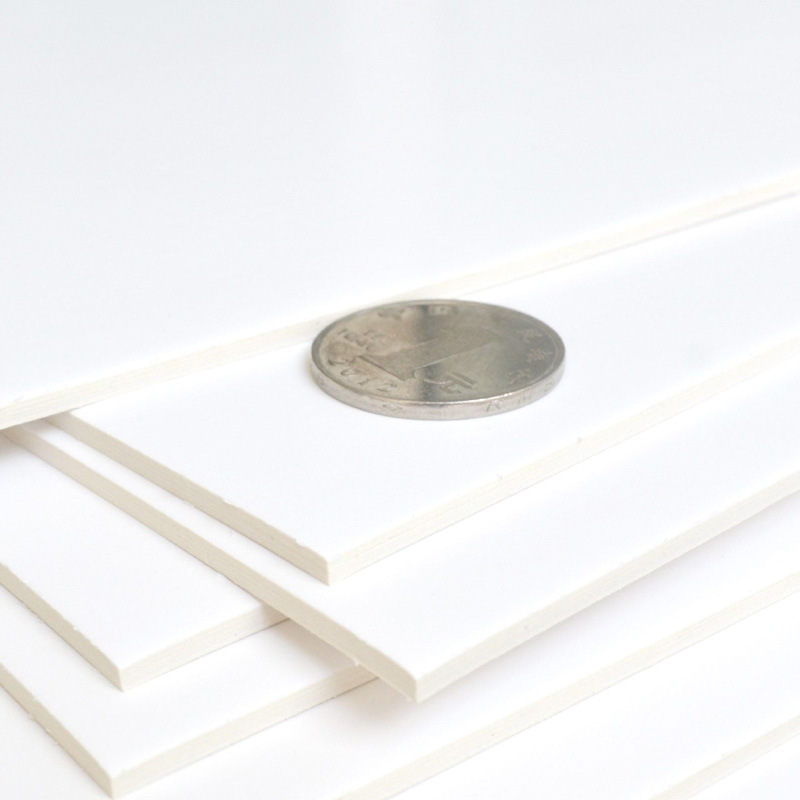

Key material attributes to check before setting equipment are grammage, caliper (thickness), burst and compression strength, coating weight, and moisture content (MC). Higher grammage and caliper increase bending stiffness and typically require deeper scores or wider creases. Coated top layers (pigment coats) resist stretching; they will crack if crease depth and radius are not matched to the board's bendability.

Critical parameters to measure

- Moisture content — measure with a calibrated meter; target range 4.5–6.5% for stable converting.

- Caliper and bulk — thicker boards need proportionally larger scoring depth and radius.

- Coating weight and type — heavy pigment coats reduce surface elongation and increase cracking risk.

Scoring and creasing: tooling, depth, and radius rules

Effective scoring removes or compresses fibres on the inside of the fold to allow a clean bend while preserving the outer face. Tooling choices include V-score, male/female crease bars, and matrix/compound dies. Select a score width, depth, and radius that match the board’s caliper and coating. The aim is to create a controlled hinge zone without rupturing the face coat.

Practical scoring guidelines by grammage

| FBB grammage (gsm) | Typical caliper (µm) | Recommended score type | Score depth / crease width | Min fold radius |

|---|---|---|---|---|

| 200–230 | ~300–400 | Standard male/female crease | 0.30–0.45 × caliper | 0.6–1.0 mm |

| 250–300 | ~400–550 | Deeper male/female or V-score | 0.35–0.55 × caliper | 0.8–1.5 mm |

| 300–350+ | ~550–750+ | Matrix die with micro-perforated score | 0.45–0.65 × caliper | 1.2–2.5 mm |

Note: "score depth" expressed as a fraction of caliper is a starting point. Fine-tune using a progressive test: increase depth until the fold passes a controlled bend test without face cracking while avoiding fibre separation on the reverse side.

Die-cutting and matrix behaviour

Die-cutting stresses the board at cut edges and near scores. For FBB paper, use hardened steel dies with appropriately spaced cut lines, and consider a sacrificial or relief zone for adjacent creases to avoid nicking the crease. Matrix dies with looseness control reduce pressure peaks that cause edge bearding or delamination.

Die-cut setup best practices

- Use a progressive pressure increase when first running a new board batch; check cut depth across the sheet.

- Maintain a minimum clearance between cut and score lines to prevent fracture propagation (recommend ≥2× caliper).

- For laminated or coated boards, maintain knife sharpness to avoid rub and heat generation that weakens coating adhesion.

Press settings, dwell, and environmental controls

Machine setup influences converting quality: anvil hardness, female matrix elasticity, and dwell time under score/crease all change outcomes. Softer anvil surfaces reduce localized compression but require deeper cuts. Ambient humidity and temperature directly shift board pliability; adjust settings when MC varies.

On-press checklist

- Record and control moisture content; recondition stock for 24–48 hours if MC differs >1% from target.

- Choose an anvil hardness that balances compression with crease definition; test 40–60 Shore A equivalents for many FBB grades.

- Use a controlled dwell (slower feed) for deep creases or heavy coatings to avoid face cracking.

Common defects, root causes and quick remedies

| Defect | Likely root cause | Immediate corrective action |

|---|---|---|

| Face cracking at fold | Score too shallow for stiffness or coating resists elongation | Increase score depth/width, use softer anvil, or pre-condition stock to higher MC |

| Paper splitting/delamination | Excessive knife pressure or brittle internal ply | Reduce cut depth, adjust blade, or use matrix with rubber backing |

| Ragged die edges (bearding) | Dull die or incorrect clearance | Sharpen or replace die; adjust clearance; slow press speed |

| Curling after fold | Imbalanced moisture or asymmetric coating | Recondition to balanced MC; add liner or backing; modify coating process |

Testing protocol and quality acceptance

Adopt standard tests: 90° fold fatigue (X cycles to failure), 180° flat fold, and visual crack scoring under 10× magnification. Document pass criteria per SKU: acceptable number of cycles before fiber break, maximum visible face cracking length, and allowable edge burr height. Use these metrics to tune press setup and supplier acceptance.

Design and supplier guidance

When specifying FBB for a product, provide target converting parameters to suppliers: desired score depth, minimum fold radius, coating formulation limits, and moisture target. Ask for sample runs and request a converter to trial the selected tooling and settings. For premium cosmetic boxes, specify matrix dies and micro-perforated scores to minimize visible cracking.

Closing recommendations

Start with conservative score depths and progress incrementally. Track environmental variables and keep tooling maintenance records. When problems persist, run a controlled set of trials varying only one parameter (score depth, anvil hardness, MC) to isolate the effect. Proper measurement, methodical testing, and tight communication with the board supplier deliver repeatable folding, creasing, and die-cutting outcomes for FBB.

English

English عربى

عربى Español

Español